PDzen PD Monitoring System

The PDzen Partial Discharge (PD) Monitoring System is an advanced solution designed for continuous, real-time monitoring of high-voltage (HV) and extra-high-voltage (EHV) electrical assets such as transformers, HV cables, air-insulated switchgear (AIS), and gas-insulated switchgear (GIS). The system comprises an industrial-grade PC with a Windows operating system and a data acquisition unit featuring one synchronization channel and three measurement channels, capable of measuring up to 10 High Voltage Channels The system is fully scalable, allowing for an unlimited number of additional channels as needed.

Why choose PDzen?

- ▶ Real-Time & 24/7 Monitoring — Continuous data collection and real-time insights for predictive maintenance.

- ▶ Highly Sensitive PD Detection — Detects partial discharge signals up to 60 MHz and as low as 20 pC.

- ▶ Scalable & Flexible — Expandable channel configurations with no upper limit.

- ▶ Cloud-Connected & Remote Diagnostics — Secure data storage and remote access via a 4G modem/router.

- ▶ Advanced Data Visualization — Interactive graphs and 3D time-domain analysis for precise diagnostics.

The system is capable of capturing and processing high-frequency noise and PD signals detected by strategically installed PD sensors. It employs a combination of capacitive, inductive, and resistive couplers to ensure accurate electrical measurement and detailed signal analysis. The PD monitoring system is highly sensitive, capable of detecting PD signals across a wide frequency range—up to 60 MHz—and signals as low as 20 pC.

The monitoring system operates as a standalone unit within a localized control cubicle, where collected data is securely stored on an SSD drive. It supports 24/7 online monitoring, ensuring real-time data collection, trending, and predictive maintenance insights. All data is readily available for download and in-depth evaluation. Additionally, the system supports remote diagnostics, allowing experts to assess PD activity as it emerges.

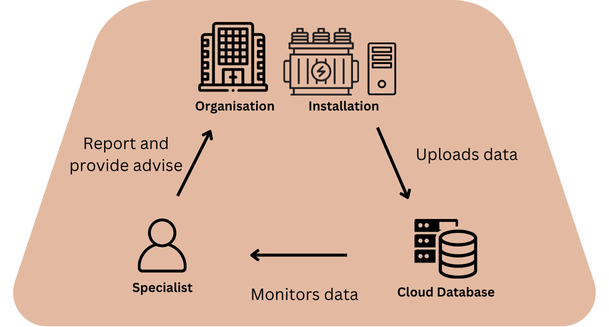

The system distinguishes between normal and abnormal PD signals. Processed abnormal data is automatically transmitted to a cloud server via a 4G modem/router, ensuring secure storage and remote access. Expert analysts interpret and evaluate the processed data, providing clients with detailed insights into the condition of their electrical assets, including cables, switchgear, and transformers.

Key Features

- ▶ Standalone Industrial PC — Secure, on-site data processing and storage.

- ▶ High-Frequency Signal Acquisition — Captures PD activity across a wide frequency range.

- ▶ Predictive Maintenance & Trending Data — Helps prevent unexpected failures and costly downtime.

- ▶ Data Visualization — Interactive 2D & 3D graphical representations of PD signals for accurate diagnosis.

- ▶ Expert Analysis & Reporting — Professional evaluation of abnormal PD data, with actionable insights.

Specifications

Communications and Connections

Ethernet 10/100 Mbps

External synchronous interface

Encrypted VPN tunnel

Protect Your Electrical Assets with PDzen

PDzen empowers utilities and industries with cutting-edge PD monitoring to ensure the safety, reliability, and efficiency of critical electrical infrastructure. Stay ahead of potential failures with real-time diagnostics and predictive maintenance.

📩 Contact us today to learn more!

※ Images shown here may not be indicative of the final product.